Concrete Rebar Scanning Daytona Beach Florida

1. Survey speed

As you should realize, because GPR transmits and receives electromagnetic waves, it can survey the same area much faster than MIRA, which sends and receives ultrasonic signals. To be more specific, it usually takes us around one to two hours to collect GPR data for an average bridge deck. However, it may take days to survey that same bridge deck with MIRA. Thus, you should be aware that MIRA may not be a good option for scanning a large concrete area.

2. Detectability

You may already know that MIRA signals cannot penetrate through air voids or delamination. Therefore, if you have a bar that lies below an air gap from concrete surface, the MIRA will not be able to detect it. On the other hand, because electromagnetic waves can travel in the vacuum, GPR will have no problem seeing such bar. To make the statement more accurate, the bar must be within the penetration depth of GPR energy.

Also regarding the detectability, for solid concrete, the MIRA signals can usually penetrate deeper that those of GPR. Thus, we should emphasize clearly this is one big benefit of using MIRA system. One may argue that he would use lower frequency GPR antenna to increase the penetration depth. However, the downsize of doing so is that you will loose GPR image resolution. In other words, you will not be able to see small objects such as rebars.

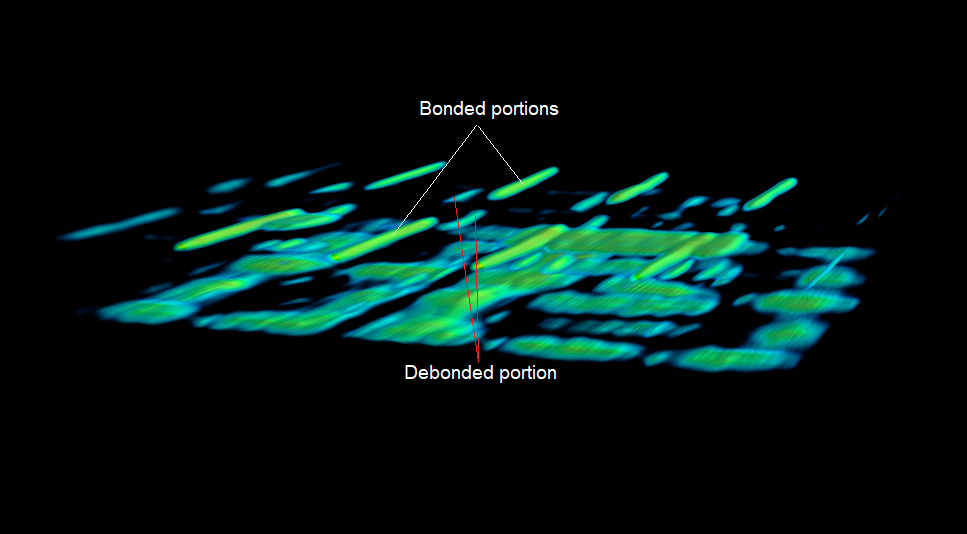

3. Concrete rebar debonding

While GPR is not able to detect steel bar debonding, Fig. 1 below shows that MIRA absolutely can. To explain, it is thanks to an effect known in the study of wave propagation as phase reversal. It happens when an incident pulse reaches the boundary between two media of which the first medium has a higher acousic impedance than that of the second medium. The consequence of it is that the reflected pulse will have a 180 degree phase change compared with the incident pulse. Thus, for a bonded rebar, the reflecting boundary will be between concrete and steel, and the phase reversal effect will not occur. On the other hand, for a debonded rebar, the reflecting boundary will be between concrete and the unbonded air gap, which will lead to phase reversal.